Production Operator

Become a Flessenier at Ciner Glass and follow your career to bottle happiness! As a Production Operator, you will be the driving force behind our production process with an eye for quality and safety.

As an Operator in our production department, you’ll be at the heart of our glassmaking operation. You’ll join one of our three sub-departments: Batch & Furnace, IS, or Mould. Each of these areas has its own specialization; from mixing and melting raw materials, to shaping glass, and maintaining the moulds.

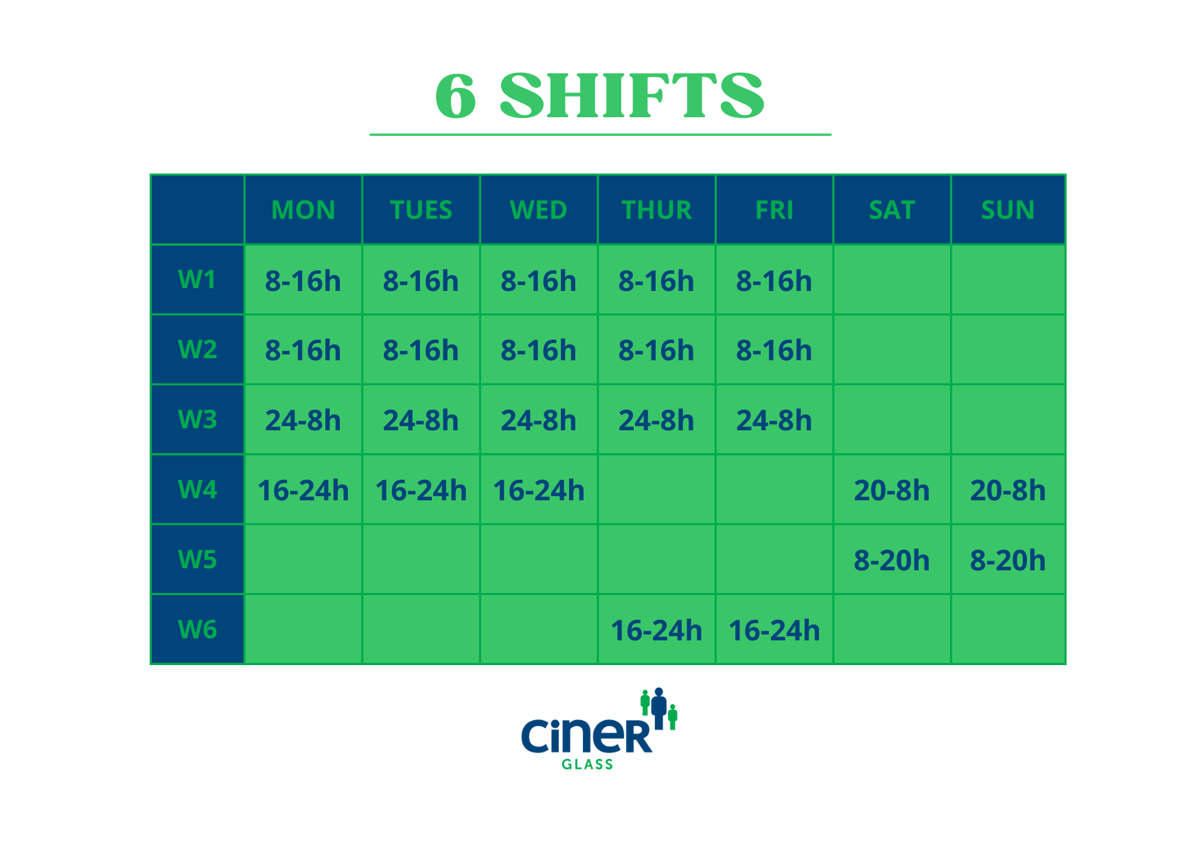

During your general training, you’ll discover every step of the process. Afterwards, you’ll continue with a role-specific training in the sub-department that best matches your skills and interests. Once your training period in day shifts is completed, you’ll start working in a 6-shift system, designed to help you maintain a healthy work-life balance.

Ciner Glass Belgium is not your average company, and this is not your average job. Here, you don’t just work with glass; you help create something that lasts. Are you ready to be part of a brand-new story in a company set to become operational in Q2 of 2026?

Are you ready to become a true Flessenier?

Are you looking for job satisfaction, or better yet, bottle happiness?

Responsibilities & Key Tasks

Within each of the operator positions, the emphasis of responsibilities and key tasks is a little different. Below is more information on what to expect within our production department:

Batch & Furnace

In this sub-department, raw materials arrive and are analyzed. Then they are formed into a recipe in the mixing plant and the recipe is heated in the furnace at 1550°C, while keeping an eye on the parameters.

- You ensure proper receipt of raw materials and glass cullet, by analyzing them and handling them correctly administratively before receipt

- You operate the mixing installations on a continuous basis from the control room and report abnormalities and try to correct them immediately

- You perform regular checks on recipes in the system, monitor silo levels and escalate if necessary

- You perform checks on raw materials, recipe, humidity, temperature, oxygen, mixers, drip or bottle samples... to keep quality, safety and hygiene high

- You regularly clean the department including mixing equipment, conveyor belts, filters, silos,...

- You act first in case of technical failures and escalate if necessary

- You ensure a stable melting process from the control room by supervising the parameters and measurements and supplementing the reports for this purpose

- You carry out certain maintenance works linked to the glass furnace

- You provide shift handover at the end of your shift to your upcoming shift

Intersection department (IS) = Glass forming department

In our IS department (glass forming department, Hot end) the molten glass arrives from the glass furnace and is cut and transported to the production line via the feeder. Here the glass drop falls into the mold and is blown and hot coated. In this department you play a key role in directing, controlling and adjusting the process, with an eye for quality and efficiency.

- You ensure a smoothly running production process by, among other things, directing and controlling the gob control, Lehr and transport systems, adjusting process parameters, checking temperature values,...

- You prepare the necessary equipment prior to conversions and replace refractory parts

- You clean and maintain the installations and working environment

- You correctly signal and report technical malfunctions and deviations

- You monitor quality by performing checks (weight, heat and temperature measurements) and keeping records such as process data, mould numbers and production settings

- You provide shift handover at the end of your shift to your upcoming shift

Mould department

This is our mould department where all moulds and certain other equipment arrive from the IS department for maintenance and/or cleaning. Quality and periodic checks are also performed here and retired parts are analyzed. New moulds are prepared and made ready to go into production.

- You perform periodic activities and checks within the department

- You are responsible for the various cleanings of the used moulds

- You perform quality checks on the moulds, report any deviations and record the control data

- You perform or follow up on calibrations

- You carry out revisions and minor repairs on damaged moulds

- Together with your colleagues, you monitor the lifespan, working hours and maintenance frequencies of the moulds

- You analyze the retired parts and discuss internally whether they can be reused

- You provide shift handover at the end of your shift to your upcoming shift

Qualifications, Skills and Experience

General

- You have experience within a manufacturing environment or are motivated to gain experience in this area

- You are open to training in day shift on different locations

- You can work with a computer

- You speak Dutch very well (English is a plus)

- You actively contribute to a pleasant team atmosphere and are helpful to colleagues

- You are flexible towards tasks, especially in the start-up phase

Batch & Furnace

- You are willing to work partly outside (reception of raw materials), partly inside in a warmer environment (with acclimatized control rooms)

Intersection department (IS) = Glass forming department

- You do not have color blindness. This is important to perform visual checks on the bottles

- You are willing to work in a warmer environment (with acclimatized control rooms)

Mould department

- You have training and/or knowledge of welding

- You have basic knowledge of mechanics

Why work at Ciner Glass?

At Ciner Glass, you’ll have the opportunity to help build a brand-new, ultra-modern production site from the ground up. You’ll take on a role you can shape yourself, in a place where pride, craftsmanship and technology come together.

This isn’t just a job; it’s a career full of bottle happiness:

- A permanent contract at Ciner Glass, with the possibility of a short interim period

- Market-conform starting gross salary

- Shift allowance ranging between 5% and 35%, depending on the shift, starting from production launch

- Training program in daytime hours before production begins

- Opportunities for training and professional development

- Bonus awarded upon reaching milestones within the training program

- Meal vouchers

- Hospitalization insurance when employed directly under a Ciner Glass contract

- Enhanced commuting allowance, including a bicycle allowance

- From the start of production: work in a 6-shift system, tailored to respect your biorhythm and family life (see below)

- 2 out of every 6 weeks in day shifts

- 4 out of every 6 weekends off

Will you be our next flessenier?

- Department

- Production

- Locations

- Ciner Glass Lommel

About Ciner Glass

Ciner Glass is more than a packaging glass producer. We’re a family business with a global perspective; driven by innovation, sustainability and people. From our bases in Turkey, the UK and Belgium, we deliver billions of glass bottles each year to the world’s leading food and beverage brands.

In 2026, we’ll open Europe’s most advanced and sustainable glass factory in Lommel. An investment of nearly €700 million, creating over 500 jobs and endless career opportunities.

This is where we bottle the future; together with you, the ‘flessenier’ of tomorrow.

Production Operator

Become a Flessenier at Ciner Glass and follow your career to bottle happiness! As a Production Operator, you will be the driving force behind our production process with an eye for quality and safety.

Loading application form