Quality Operator

Become a Flessenier at Ciner Glass and follow your career to bottle happiness! As a Quality Operator, you will be the driving force behind our production process with an eye for quality and safety.

As an Operator in our Quality & Cold End Department, you’ll play a crucial role in the final phase of the production process. This is where bottles are gradually cooled, inspected for defects and coated for protection; all under your watchful eye.

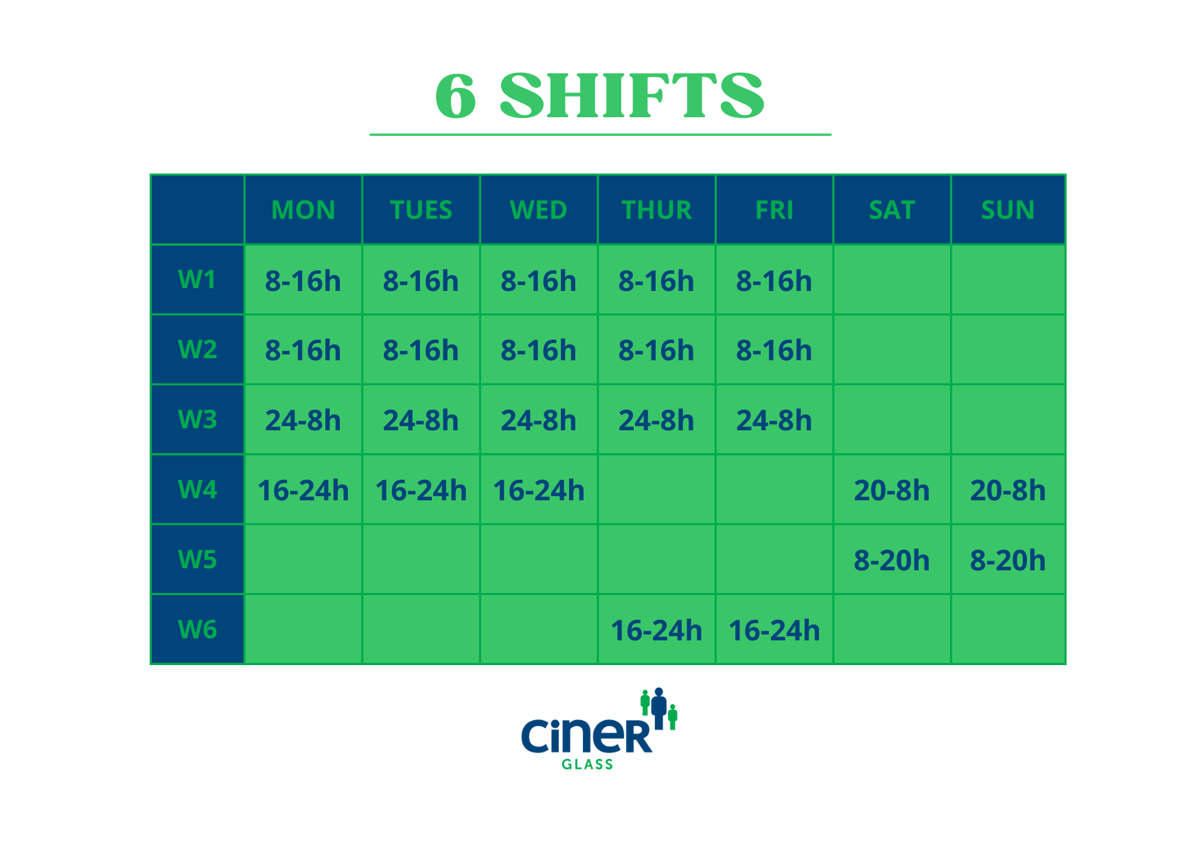

During your general training, you’ll discover every step of the process. Afterwards, you’ll continue with a role-specific training in the sub-department that best matches your skills and interests. Once your training period in day shifts is completed, you’ll start working in a 6-shift system, designed to help you maintain a healthy work-life balance.

Ciner Glass Belgium is not your average company, and this is not your average job. Here, you don’t just work with glass; you help create something that lasts. Are you ready to be part of a brand-new story in a company set to become operational in Q2 of 2026?

Are you ready to become a true Flessenier?

Are you looking for job satisfaction, or better yet, bottle happiness?

Responsibilities & Key Tasks

Within each of the operator positions, the emphasis of responsibilities and key tasks is a bit different. Below is more information on what to expect within our Quality & Cold End department:

This department operates independently of all other departments to ensure objectivity regarding quality. The Quality department plays a crucial role in ensuring the quality and safety of the glass bottles produced. Within the Cold End section, the formed glass is cooled, inspected, handled and packaged - that is, everything that happens after the forming and annealing of the glass.

- You perform quality checks during production regular checks on products during production (e.g. bottle thickness, weight, shape, cracks or air inclusions) as well as checking that products meet specifications and standards (such as ISO standards or customer specifications)

- You take care of visual inspection and automatic quality detection using automatic inspection systems that detect defects such as cracks, deformations or contamination

- You assess rejected products and determine whether they are real defects or false reports

- You are responsible for analyzing rejects and defects to find the cause (e.g. wrong temperature, wrong mould setting) and feedback to production to improve processes

- Performing physical (manual) tests on glass such as pressure tests, thermal shock resistance and chemical resistance, as well as color measurements or tests on coatings (such as barrier layers or decoration) are part of your duties

- You follow the flow around the application of coating (making the glass more scratch resistant, reducing friction between bottles, offering protection during further processing)

- You record the measurement results and deviations in the context of problem solving, analyses and traceability

- You solve first line failures independently

- For another type of product, you adjust the production line, set up camera positions and take care of the necessary parameterization in the various devices

Qualifications, Skills & Experience

General

- You have experience within a manufacturing environment or are motivated to gain experience in this area

- You are open to training in day shift, where flexibility is important towards content

- You can work with a computer

- You speak Dutch very well (English is a plus)

- You actively contribute to a pleasant team atmosphere and are helpful to colleagues

- You are flexible towards tasks, especially in the start-up phase.

Quality & Cold End department

- You are not color blind. This is important to carry out visual checks on the bottles

- You have technical knowledge to solve the first malfunctions as well as make the necessary adjustments to the production lines

- You work very accurately. After all, you are working with a product that enters the food chain

Why work at Ciner Glass?

At Ciner Glass, you’ll have the opportunity to help build a brand-new, ultra-modern production site from the ground up. You’ll take on a role you can shape yourself, in a place where pride, craftsmanship and technology come together.

This isn’t just a job; it’s a career full of bottle happiness:

- A permanent contract at Ciner Glass, with the possibility of a short interim period

- Market-conform starting gross salary

- Shift allowance ranging between 5% and 35%, depending on the shift, starting from production launch

- Training program in daytime hours before production begins

- Opportunities for training and professional development

- Bonus awarded upon reaching milestones within the training program

- Meal vouchers

- Hospitalization insurance when employed directly under a Ciner Glass contract

- Enhanced commuting allowance, including a bicycle allowance

- From the start of production: work in a 6-shift system, tailored to respect your biorhythm and family life (see below)

- 2 out of every 6 weeks in day shifts

- 4 out of every 6 weekends off

Will you be our next flessenier?

- Department

- Quality

- Locations

- Ciner Glass Lommel

About Ciner Glass

Ciner Glass is more than a packaging glass producer. We’re a family business with a global perspective; driven by innovation, sustainability and people. From our bases in Turkey, the UK and Belgium, we deliver billions of glass bottles each year to the world’s leading food and beverage brands.

In 2026, we’ll open Europe’s most advanced and sustainable glass factory in Lommel. An investment of nearly €700 million, creating over 500 jobs and endless career opportunities.

This is where we bottle the future; together with you, the ‘flessenier’ of tomorrow.

Quality Operator

Become a Flessenier at Ciner Glass and follow your career to bottle happiness! As a Quality Operator, you will be the driving force behind our production process with an eye for quality and safety.

Loading application form